To generate electricity from biomass gasification, we first convert organic materials, like wood and agricultural waste, into syngas through a thermochemical process involving drying, pyrolysis, reduction, and combustion. This syngas, primarily composed of 30-60% carbon monoxide (CO) and 25-30% hydrogen (H₂), can then fuel internal combustion engines or gas turbines. By employing efficient gasifier designs, such as fixed or fluidized beds, we can optimize syngas quality and yield. In addition, integrating heat recovery systems maxes out energy efficiency, making biomass gasification a viable renewable energy source. Additional insights may enhance our understanding of this process.

Key Takeaways

- Biomass gasification converts organic materials into syngas through a four-stage process: drying, pyrolysis, reduction, and combustion.

- Syngas, primarily composed of hydrogen and carbon monoxide, powers internal combustion engines and gas turbines for electricity generation.

- Various gasifier designs, such as fixed bed and fluidized bed, optimize syngas quality and yield, enhancing overall energy output.

- Heat recovery systems integrated into gasification processes improve energy efficiency and increase electric power production.

- Biomass gasification supports renewable energy initiatives, reducing greenhouse gas emissions and reliance on fossil fuels while offering competitive energy costs.

Overview of Biomass Gasification

Biomass gasification is an innovative process that transforms organic materials into valuable energy sources. By employing advanced biomass gasification technology, we can convert agricultural and industrial waste into syngas through a thermochemical reaction involving thermal decomposition under limited oxygen. This gasification process consists of key stages, including drying, pyrolysis, reduction, and combustion, ultimately yielding producer gas rich in hydrogen, carbon monoxide, and methane. The output syngas serves myriad applications, particularly in electricity generation and renewable energy production, making it a cleaner alternative to traditional combustion methods. With different gasifier designs, such as fixed bed and fluidized bed systems, the quality and yield of syngas can vary, prompting ongoing research to optimize these technologies for diverse biomass feedstocks.

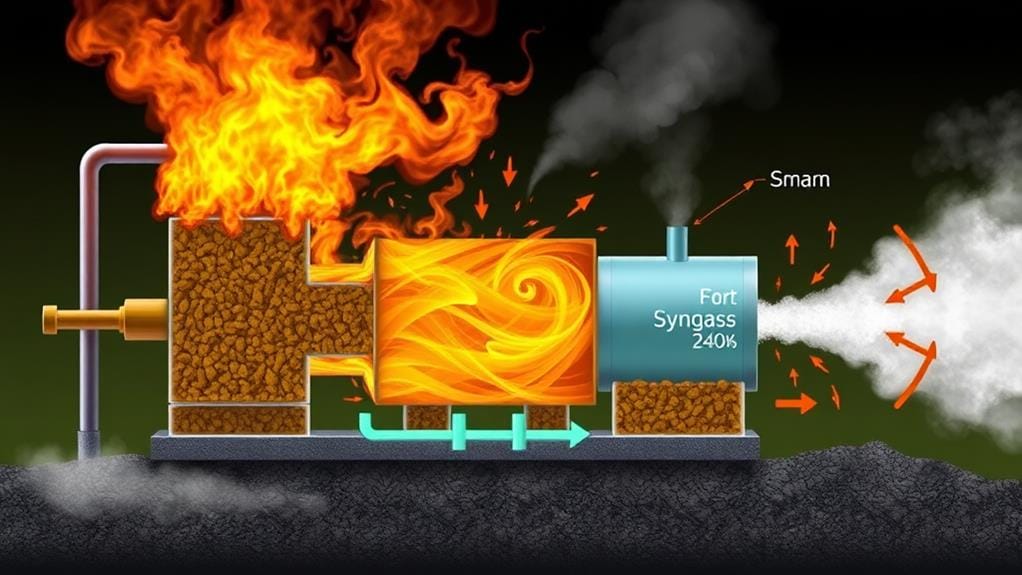

The Gasification Process

Understanding the gasification process helps us appreciate how organic materials can be transformed into usable energy. Biomass gasification is a thermochemical method that converts biomass into syngas, primarily through high-temperature reactions with controlled oxygen and steam. This intricate process unfolds in four stages: drying, pyrolysis, reduction, and combustion. Each phase plays an essential role in breaking down solid biomass, such as wood waste and agricultural residues, into a gaseous fuel. Gasifiers, either fixed bed or fluidized bed types, are designed to optimize syngas yield and quality. By employing heat recovery systems and integrating steam turbines, we can enhance the efficiency of gasification, ultimately maximizing energy output and ensuring sustainable energy solutions for our communities.

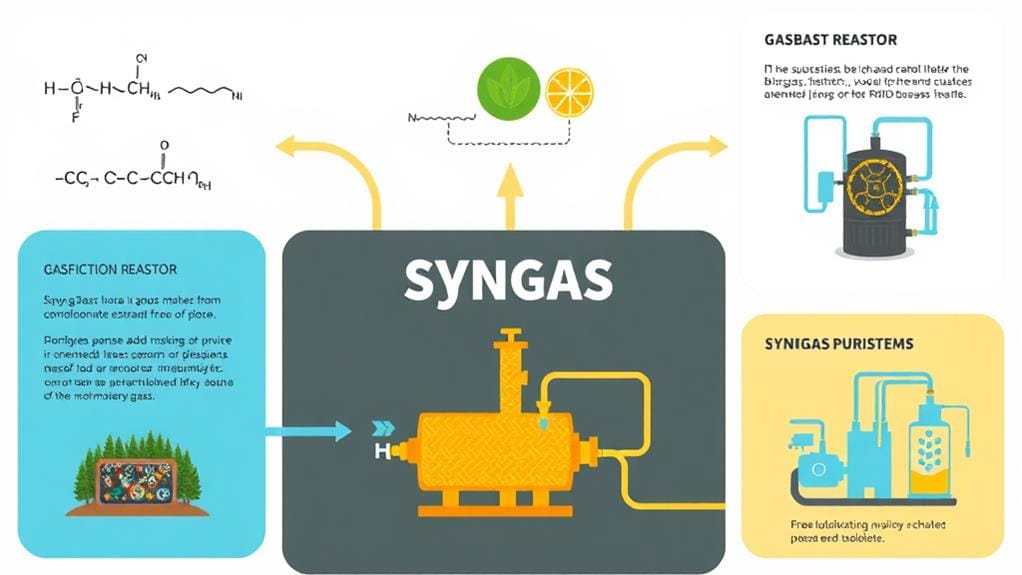

Components of Syngas

During the gasification process, syngas emerges as an important product, boasting a composition that primarily includes hydrogen (H₂) and carbon monoxide (CO). Typically, in biomass gasification, particularly with woody biomass, we find that syngas contains approximately 30-60% CO and 25-30% H₂. The molar ratio of hydrogen to carbon monoxide generally ranges from 0.5 to 3, which greatly influences its suitability for various applications, including power generation and renewable fuel production. Additionally, syngas may contain smaller amounts of carbon dioxide (CO₂), methane (CH₄), and other trace gases, impacting its overall energy content and combustion characteristics. It's vital to recognize that the quality and composition of syngas can vary based on feedstock, gasifier design, and operational conditions, affecting efficiency and emissions.

Applications of Syngas

Harnessing the potential of syngas opens up a world of applications that extend far beyond mere energy generation. By leveraging biomass gasification, syngas can transform various industries and enhance our collective sustainability efforts. Here are three key applications:

- Electricity Generation: Syngas fuels internal combustion engines and gas turbines, enabling efficient and reliable power production.

- Fischer-Tropsch Process: This process utilizes syngas to synthesize liquid hydrocarbons, paving the way for biofuels and lubricants derived from biomass resources.

- Ammonia Synthesis: Syngas is essential in the Haber process, facilitating the production of fertilizers important for agricultural productivity.

Environmental Benefits

Biomass gasification offers considerable environmental benefits that can transform our approach to energy production. By utilizing organic waste as a feedstock, biomass gasification can reduce greenhouse gas emissions by up to 90% compared to fossil fuel combustion, greatly aiding our climate change mitigation efforts. In addition, this process diverts approximately 4 billion tons of organic waste from landfills, which decreases methane emissions from decomposition. It also requires 14-24% less water than traditional coal-based generation, promoting sustainable water use. Moreover, converting biomass into syngas supports carbon neutrality initiatives, while integrating carbon capture and storage technologies can capture CO2 emissions before they enter the atmosphere, enhancing our efforts to combat climate change impacts effectively.

Economic Considerations

The environmental advantages of biomass gasification set the stage for examining its economic aspects. Understanding the economic feasibility of biomass gasification power plants is essential, as several factors come into play:

- Local biomass availability influences fuel costs and operational expenses, determining the project's viability.

- Government policies and incentives can greatly affect funding, shaping market dynamics and attracting investment interest.

- Job creation opportunities in rural areas arise from biomass collection and processing, fostering local economies.

With levelized costs ranging from $0.08 to $0.15 per kWh, biomass gasification systems are competitive with conventional energy sources. By traversing these economic considerations, we can better assess the potential benefits and sustainability of biomass gasification projects in our communities.

Technologies and Innovations

As we explore the advancements in biomass gasification, it's essential to understand how advanced thermal conversion technologies are transforming feedstock variety and management while greatly reducing emissions. By incorporating innovative emission reduction technologies, we can enhance the environmental performance of biomass gasification systems, leading to cleaner energy outputs. In addition, the integration of diverse feedstocks not only improves sustainability but also allows for optimized processes that increase overall efficiency and effectiveness in electricity generation.

Advanced Thermal Conversion

With advancements in thermal conversion technologies, we're witnessing a considerable transformation in how we generate electricity from biomass. These innovations enable us to harness biomass energy efficiently, turning it into syngas through processes like gasification. Here are three key aspects of advanced thermal conversion:

- Multi-stage Process: The gasification process involves drying, pyrolysis, reduction, and combustion, ensuring maximized energy extraction.

- Gasifier Types: Different gasification plant designs, such as fixed bed and fluidized bed systems, optimize gas quality and yield.

- Heat Recovery Integration: Incorporating heat recovery systems enhances overall efficiency, considerably boosting electric power production.

Feedstock Variety and Management

In exploring feedstock variety and management for biomass gasification, we find that the flexibility of feedstock options plays a crucial role in enhancing energy production. Biomass feedstock, including wood waste, agricultural residues like corn husks, and municipal solid waste, allows us to utilize diverse resources effectively. However, effective feedstock management requires pre-processing steps, such as drying and size reduction, to control moisture content, which can markedly impact energy yield. The variability in biomass characteristics necessitates advanced monitoring technologies to maintain stable gasification conditions for peak syngas production. Innovations in automated fuel feeding systems and moisture control enhance operational efficiency. Additionally, co-gasification of different biomass types can maximize syngas yield while minimizing tar formation, showcasing the potential benefits of blending feedstocks.

Emission Reduction Technologies

While we endeavor for cleaner energy solutions, the role of emission reduction technologies in biomass gasification has become increasingly essential. By integrating advanced systems, we can greatly minimize our ecological footprint. Here are three key advancements:

- Carbon Capture and Storage (CCS): This technology captures CO2 emissions during gasification, aiding in our carbon neutrality goals.

- Fluidized Bed Gasifiers: These innovative reactors promote efficient biomass conversion, reducing nitrogen oxides (NOx) emissions compared to traditional methods.

- Heat Recovery Systems: Implementing these in gasification plants enhances energy efficiency, minimizing waste heat and further decreasing greenhouse gas emissions.

Future of Biomass Gasification

As we look ahead to the future of biomass gasification, it's clear that technological advancements will play an essential role in shaping its viability as a renewable energy source. With innovations like high-temperature entrained flow gasification and hybrid systems, we're likely to see significant improvements in conversion efficiency and reduced tar production, which will enhance the overall performance of these systems. Additionally, the effectiveness of supportive policies and incentives will be paramount in driving investment and public awareness, ultimately determining how quickly biomass can replace a substantial portion of fossil fuel use, particularly as we aim for a potential 20% shift in energy sourcing in regions like Europe and developing nations.

Technological Advancements Ahead

Increasingly, researchers are focusing on technological advancements in biomass gasification to release its full potential for sustainable energy generation. As we explore this exciting field, we can envision several key innovations that will shape our future energy systems:

- Optimized reactor designs, enhancing efficiency and reducing tar production for improved gas quality.

- Supercritical water gasification, which may yield higher efficiencies than traditional methods, allowing us to convert waste into energy more effectively.

- Hybrid systems that integrate biomass gasification with renewable technologies like solar and wind, promoting reliability and sustainability.

These advancements not only aim to enhance gas production and efficiency but also align with our commitment to Environmental Protection, paving the way for a cleaner, more sustainable energy landscape.

Policy and Incentives Impact

The success of biomass gasification projects often hinges on effective policy frameworks and incentives that support their development. Government policies, including Renewable Energy Standards (RES) and Renewable Portfolio Standards (RPS), considerably enhance market demand for biomass energy, thereby facilitating essential funding and investment in gasification technologies. Tax credits, grants, and subsidies specifically aimed at renewable energy sources can greatly lower capital costs, making biomass gasification more competitive with fossil fuel alternatives. Additionally, as the recognition of biomass gasification's potential to contribute to carbon neutrality and sustainability goals increases, its integration into national and regional energy strategies becomes more likely. Ongoing research and advocacy efforts are critical for fostering public awareness, ultimately influencing more favorable policies and regulations for this promising technology.

Frequently Asked Questions

How to Produce Electric Power From Biomass Gasification?

To produce electric power, we must consider feedstock selection and gasifier design. Together, we can address energy efficiency, emission control, and operational challenges, ensuring economic feasibility while utilizing diverse biomass sources for sustainable energy solutions.

How Does Gasification Produce Electricity?

In exploring how the gasification process generates electricity, we recognize its efficiency factors and various gasifier types. By harnessing biomass sources, we can enhance energy conversion while minimizing environmental impact through technology advancements.

What Is Biomass Gasification for Power Generation?

Imagine a green engine churning from nature's leftovers. We explore biomass gasification for power generation, focusing on feedstock selection, the gasification process, and its thermal efficiency, showcasing technology advancements and environmental impact. Join us!

How Much Electricity Can Be Generated From Biomass?

When we explore how much electricity can be generated from biomass, we find diverse biomass types offering varying efficiency rates. Our feedstock selection and gasification technologies impact energy conversion and economic feasibility, all while considering environmental impact.